Decortication and Extraction

Processing Hemp

Cannabis Fiber.Seed.Oil

The potential for growth for hemp biofiber production and processing is significant. The Processing Plant will focus on a selected small number of well developed and accessible markets and uses that have a range of quality requirements.

Processing the base materials, hurd, and bast, as the foundation for Hygiene, Home/Office, Industrial, Healthcare, Geo-textiles, Agricultural, Construction, Home Furnishings, Automotive, and Clothing Components. These have distinct environmental and health benefits which the market demands.

Current raw materials for many products use environmentally unfriendly materials. For example, Cat Litter uses clay, paper or gels as absorbents. They can clog plumbing and sewer systems, use unsustainable wood from trees, cause respiratory issues, clay can swell up to 15 times its original volume causing health issues or clogging pipes if unintentionally put in the drain, and is mined. This is a processing system to produce the two base materials, hurd and bast, for Cat litter, HVAC filters, Plant Protein, Resin Cannabinoids, building blocks, absorbents for petroleum spills, erosion control products, couch fillers, and more.

Picture shows a fiber First Field on top and a resin field below

Fiber as a primary processing material creates multiple revenue streams from the Bast, Hurd, and dust. By growing for fiber it is possible to achieve quality secondary products, seed, and resin/cannabinoid oils. This would require decortication, extraction/distillation, hulling, expeller, bagging, needle press, and other additional machines.

Environmentally & Technologically Advanced Materials

Tech

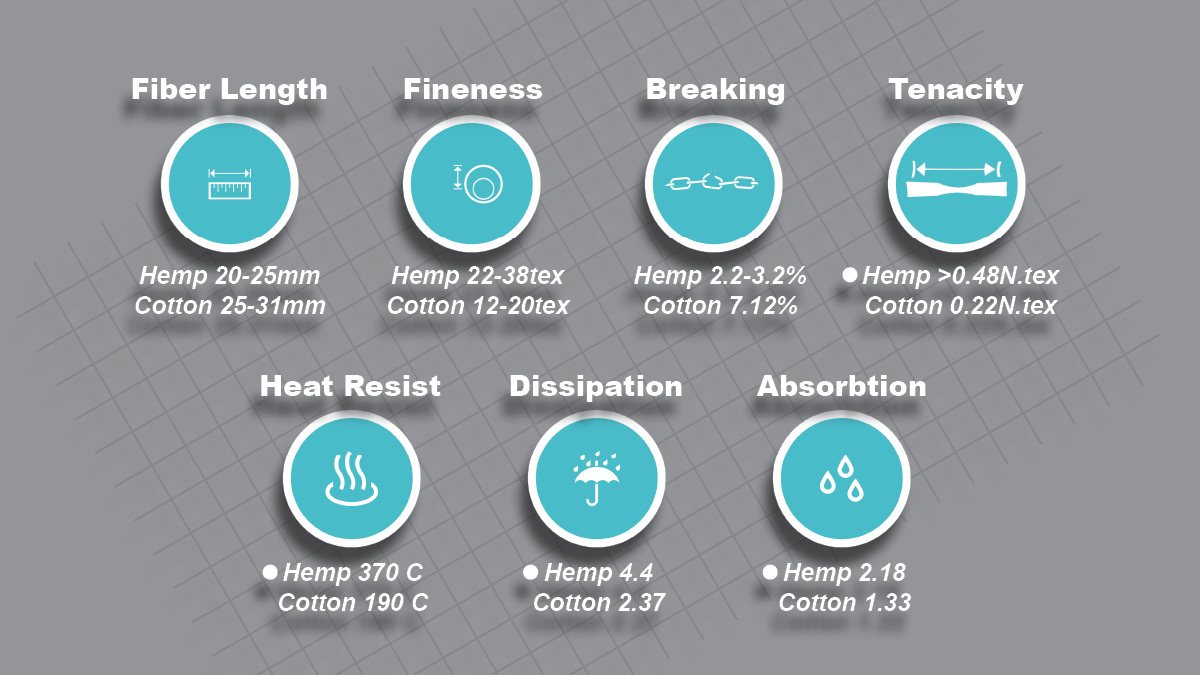

The fiber component of the Cannabis plant has many technical attributes that offer additional benefits to existing products, these include high tensile strength, high rate of absorbency and high rate of drying, anti-microbial, and UV resistance. These are features that are above and beyond what many source materials have.

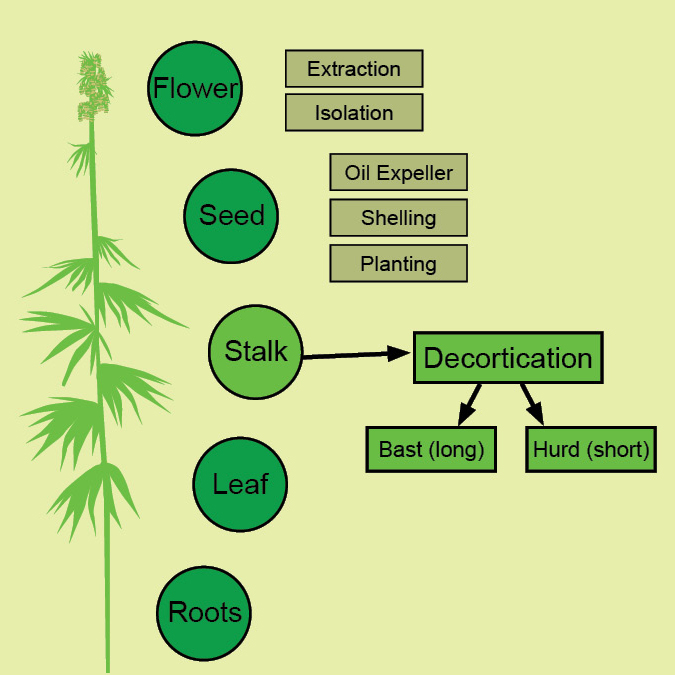

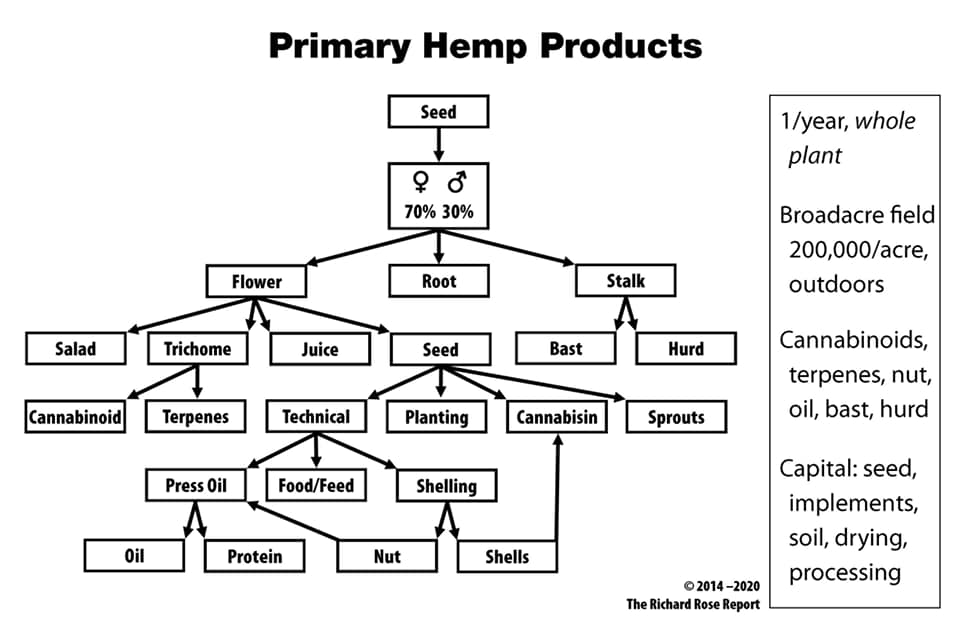

Parts of the Plant

Parts of the plant include fiber, seed, and flower for production. All of the parts have value.

Markets

Base Materials

Process

Fiber-grown hemp is much less labor-intensive than CBD hemp.

The plant must be partially decomposed in a process called retting, followed by a crushing process called decortication that breaks the bark away and releases the fiber. For specific applications the fiber then must be de-gummed and combed, this is necessary before it can be spun into yarn, which then can be woven into a fabric.

Machines

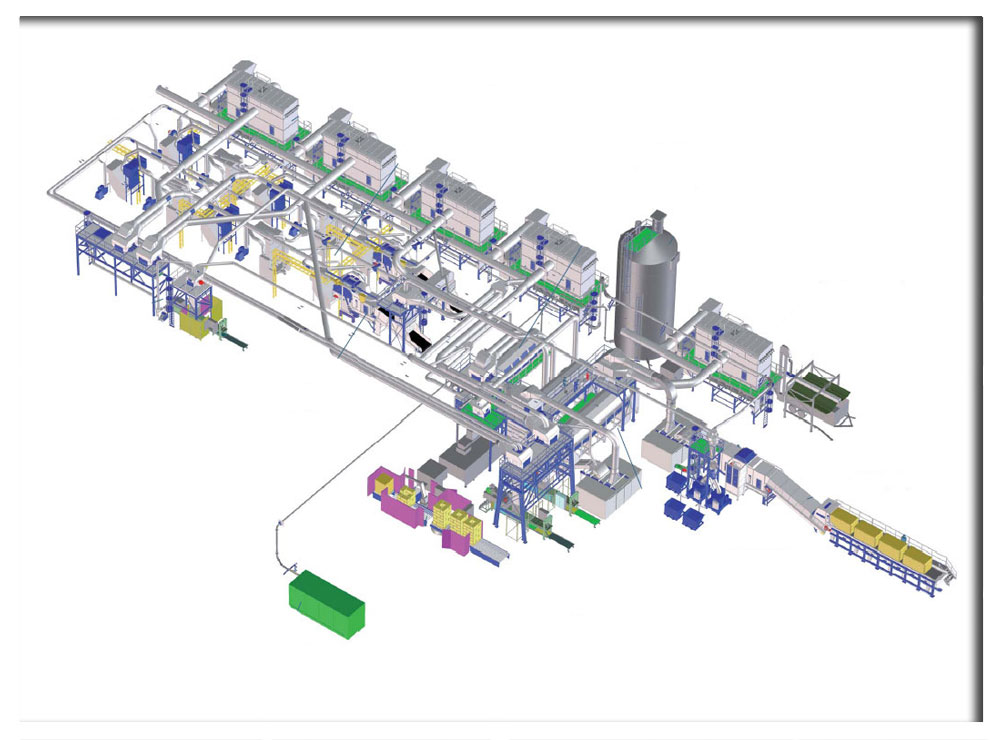

Description TemaCrete Line

This decortication line processes 40 thousand tons of hemp fiber per year, using 16,000 acres of hemp.

The first main part of the line is the Decortication section, this provides fiber with an average 15% of core.

- loading conveyor with a metal detector to prevent damage to the infrastructure

- guillotine cutter for round bales

- straw opener

- Underneath is a connection to an integrated stone catcher

- First decorticator, with spark detection and straw extraction and air-separator for the first core separator. This leads to the second decorticator and second core separator. Dust transport to briquetting machine.

The second section is for refining resulting in fiber with 3-8% of the core.

- A hopper feeder with air-separator

- First step-cleaner

- Second fine opener and air-separator

- Second step-cleaner

- Dust transport to briquetting machine

- Automatic fiber baling press with a pressing force of 40 tons and a capacity of 1,200 kg/h.

- Core collection and internal transportation systems

- Air separator for collection of core from the refining section

- 2 Air-locks and blower for the core

- Core cleaning section

- Collection system under the separators

- elevator

- cleaning drum for short fibers of paper grade

- A silo for core storage

- Automatic baling press for large packages

- Briquetting press for the dust

- Last step processing machines

- pelletizer

- needle press

- etc.

PRODUCTS

The seed can be used as a food item, pressed into a food grade-oil, soaps, animal and bird feed, technical oils and lubricants.

Start with all the primary products.

Market Size

Implementing fiber as a primary pipeline, it is possible to create multiple economic streams which can supplement up to and beyond 15% of materials for products such as:

-

- Concrete building block production

- Cat litter in North America is $15.6 Billion

- HVAC filters is projected to grow to $6 Billion in 2024

- Plant Protein market is $12.1 Billion and expanding

- Resin Cannabinoid is expected to grow to $20 Billion by 2020

- Other markets include paper, straws and cardboard, building blocks, absorbents for petroleum spills, erosion control products, couch fillers, and more.

Team

“As the leading light of Cannabis, Mr. Hemp has helped move the mountain of over 80 years of prohibition”

“As a partner in Global Industry Standard, one of 12 original companies Pennsylvania trusted with a hemp cultivation permit, Mr. Mussare has participated in all aspects of hemp cultivation, processing, and final product to market.”

OPPORTUNITY & COMPETITION

There are opportunities available to explore selling to the federal government through the USDA’s BioPreferred Program, which encourages government procurement of “biobased” products to “create new jobs and provide new markets for farm commodities,” according to the agency.

Paper and carton/cardboard companies are interested in using hemp fiber as a supplemented material in the production of commercial products.

CURRENT FAILURES IN THE US

Existing companies such as Hemp Incorporated, who purchased a used decortication line from Diamond Tobacco in 2014, have yet to turn on their machinery due to a series of issues.

Poor yields and quality of fiber and style of growing.

This will be labor-intensive, until the correct equipment and processing infrastructure is implemented.

Not the right people

Many of the people who are the best to run operations like these are not in the public eye and some are excluded from working in the industry due to unequal regulatory practices.

Not understanding the market

Many of the existing companies are farming for CBD and growing plants like an indoor garden and this method creates unusable fiber for a decortication line. There is a need for people with a background in material formulation and it needs to be balanced with young people who are studying the current technology changes at university.

Sunstrand’s bankruptcy filing comes as fiber manufacturers struggle to find markets for their products and state officials complain that the hemp industry is facing “bureaucratic paralysis” because of federal inaction on CBD regulations.

BARRIERS TO ENTRY

- Due to the shuttered textiles industry in the USA, there is a lack of infrastructure for processing.

- There is not enough supply of quality raw materials.

ROI on the TemaCrete decortication line

For the TemaCrete quality decortication system with the capacity to meet the demand of potential clients, the modification and reengineering of the equipment and the construction of the plant is expected to require approximately 12 months, followed by two full years of limited production during the testing of the processing and products. Hemp Cleans is projected to achieve $3 million in revenue in the first 11 months of operations, after the construction of operations, growing to $10.32 million in 3 years.

Based on a gross margin of 47%, Hemp Cleans achieves break even with approximately $8.1 million in revenues in 3 years, or at approximately 79% of the 3rd year projected revenues.

Hemp crops can yield about anywhere between 2.5 to 3 tons of hemp fiber per acre, after costs farmers can make upwards of $480 per acre in profit.

Technical standards must be set for the specific needs of the products developed from a decortication line. These include a minimum length of fiber (meaning no branches), consistent diameter from bottom to top of the plant, ratios of bast and hurd in the core of the plant, seed flavor, size and oil content, and many other variables. A breeding program is a key component to guaranteeing the plant grown is the best it can be for the decortication line. A direct relationship with the farmers is critical for efficient and quality operation.

Financials

| Line | Cost | Ton/year | Quality |

|---|---|---|---|

| Environ- Machine |

$100,000.00 | Medium | |

| D-8 | $300,000.00 | 4T to 16T per year | Low |

| HempTrain | $1,850,000.00 | 5,500T per year | Medium |

| TemaCrete | $6 million Buildout $17 million |

40k T per year | High |